The following guidelines are specifically for beadlock wheels and should help with installing your beadlock rings:

- Beadlock wheels are built for off highway and racing purposes and are not intended for regular highway use.

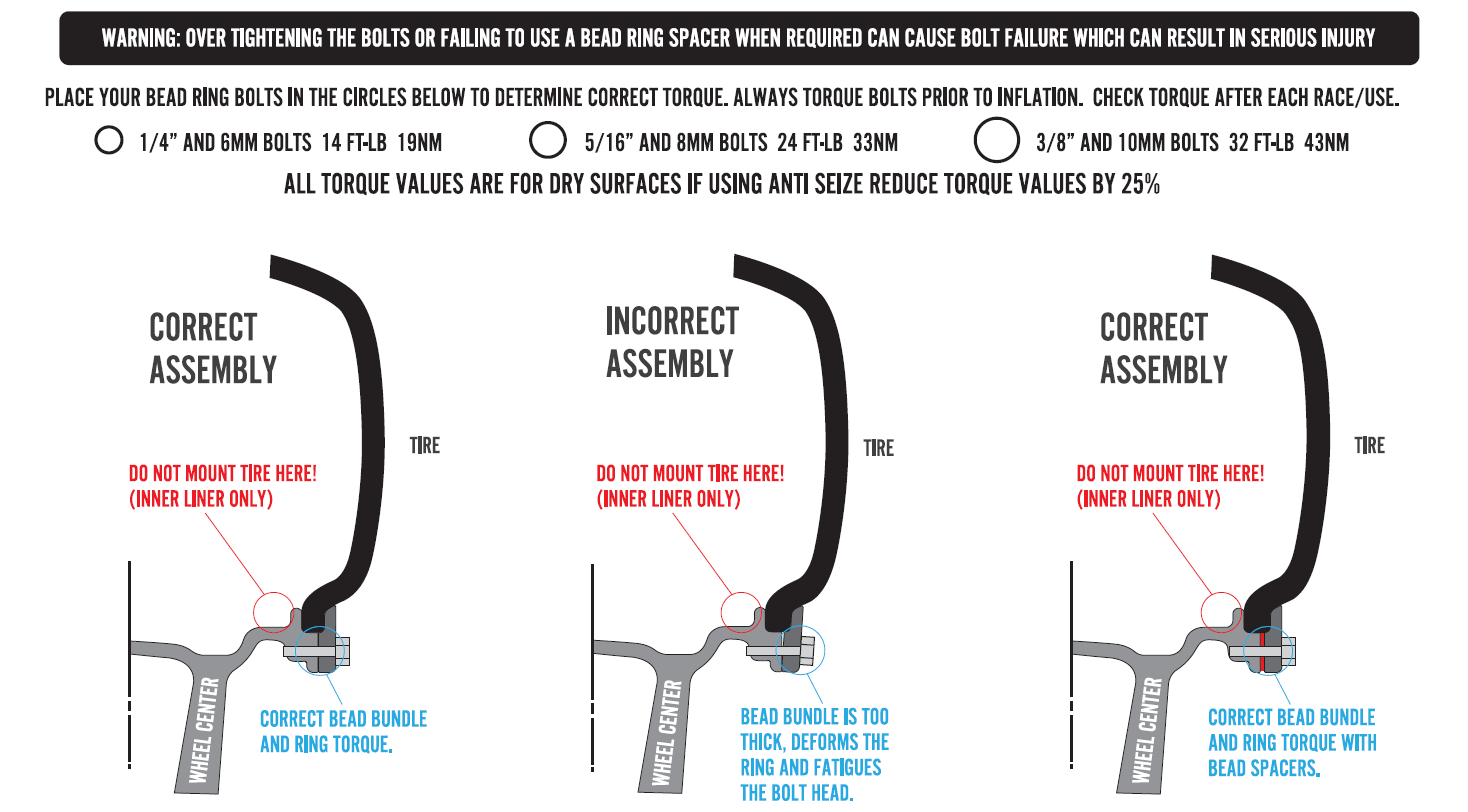

- Tires should only be installed by a professional tire installer with beadlock wheel experience. Tire inflation should be done inside an approved safety cage. It is important to make sure the tire front bead is installed on the wheel as shown below.

- Beadlock wheels can lose air pressure faster than a typical street wheels and should be checked before each use.

- Torque assembly bolts to the torque specified below based on the bolt diameter. Only use the bolts supplied with the wheel or ring spacer. Bolts should first be tightened in small increments in a circular pattern to draw the tire into the mounting seat of the wheel. After the tire is completely seated final torque should be set using a star pattern on all bolts. Repeat the star pattern two more times.

- Verify if your tires require a bead ring spacer. Tire bead thickness varies by manufacturer. If the bead ring is bending inward during installation and is lower on the side closest to the center of the wheel as shown below a ring spacer may be required.

Torque Summary:

- 1/4 inch and 6mm bolts: 14 ft-lb or 19 Nm

- 5/16 inch and 8mm bolts: 24 ft-lb or 33 Nm

- 3/18 inch and 10mm bolts: 32 ft-lb or 43 Nm

WARNING: OVER TIGHTENING THE BOLTS OR FAILING TO USE A BEAD RING SPACER WHEN REQUIRED CAN CAUSE BOLT FAILURE WHICH CAN RESULT IN SERIOUS INJURY.

To ensure the rings are torqued properly, it's recommended that you use the following pattern when tightening the bolts:

For more on installing beadlocks, check out this video: Installing Beadlocks

Comments

0 comments

Please sign in to leave a comment.